Production Process Videos

Panoorin ang aming advanced manufacturing process in action

Rigid-Flex PCB Laser Cutting

Precision laser cutting para sa rigid-flex PCB separation

Rigid-Flex PCB Laser Cutting Part 3

Advanced laser depaneling technology demonstration

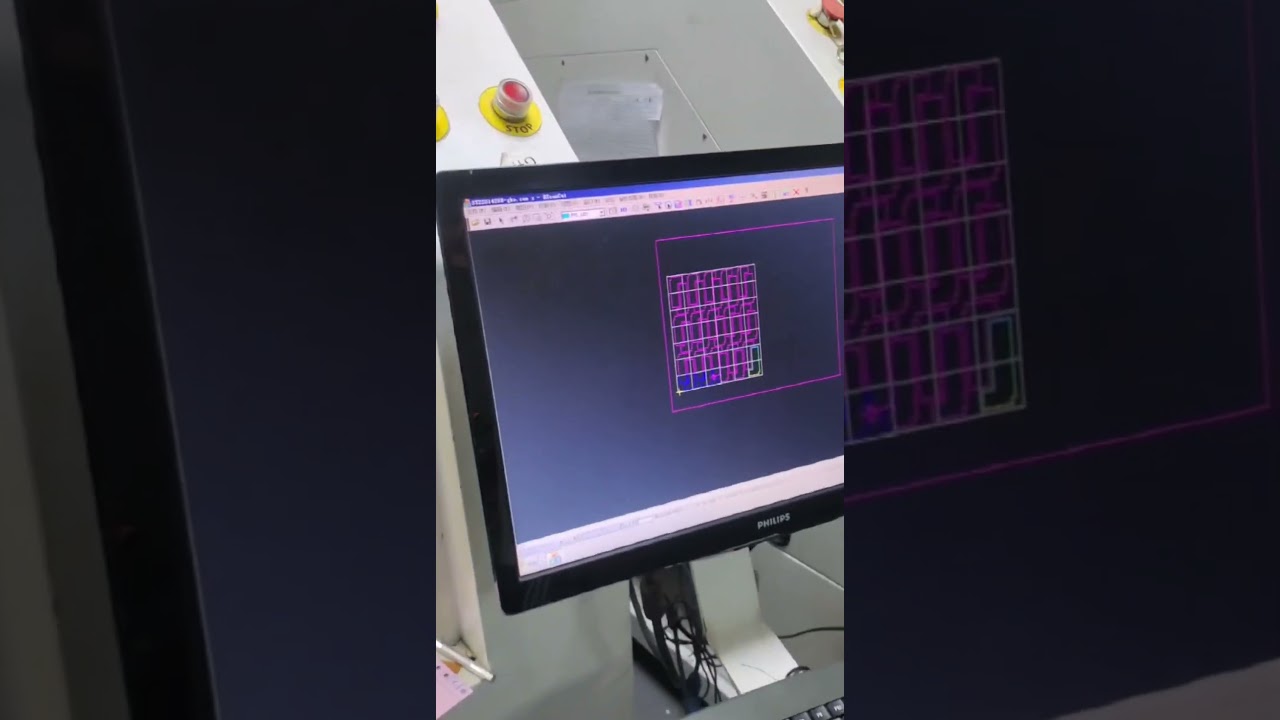

Flexible Print Board Depaneling

Flexible PCB depaneling process